When it comes to modern electrical installations, carefully organising and protecting cables isn’t just about neatness—it’s about safety, longevity and future-proofing. With that in mind, let’s explore how TMT Plus offers effective solutions, and specifically how using conduit electrical wiring can transform your wiring system.

In any building—residential or commercial—cables run through walls, floors and ceilings. Without proper protection and routing, they’re vulnerable to moisture, accidental damage, and even rodents. That’s why choosing the right pipe systems, junctions, and conduit runs is critical. A system with the right piping and accessories is easier to maintain, safer to inspect, and more reliable in the long run.

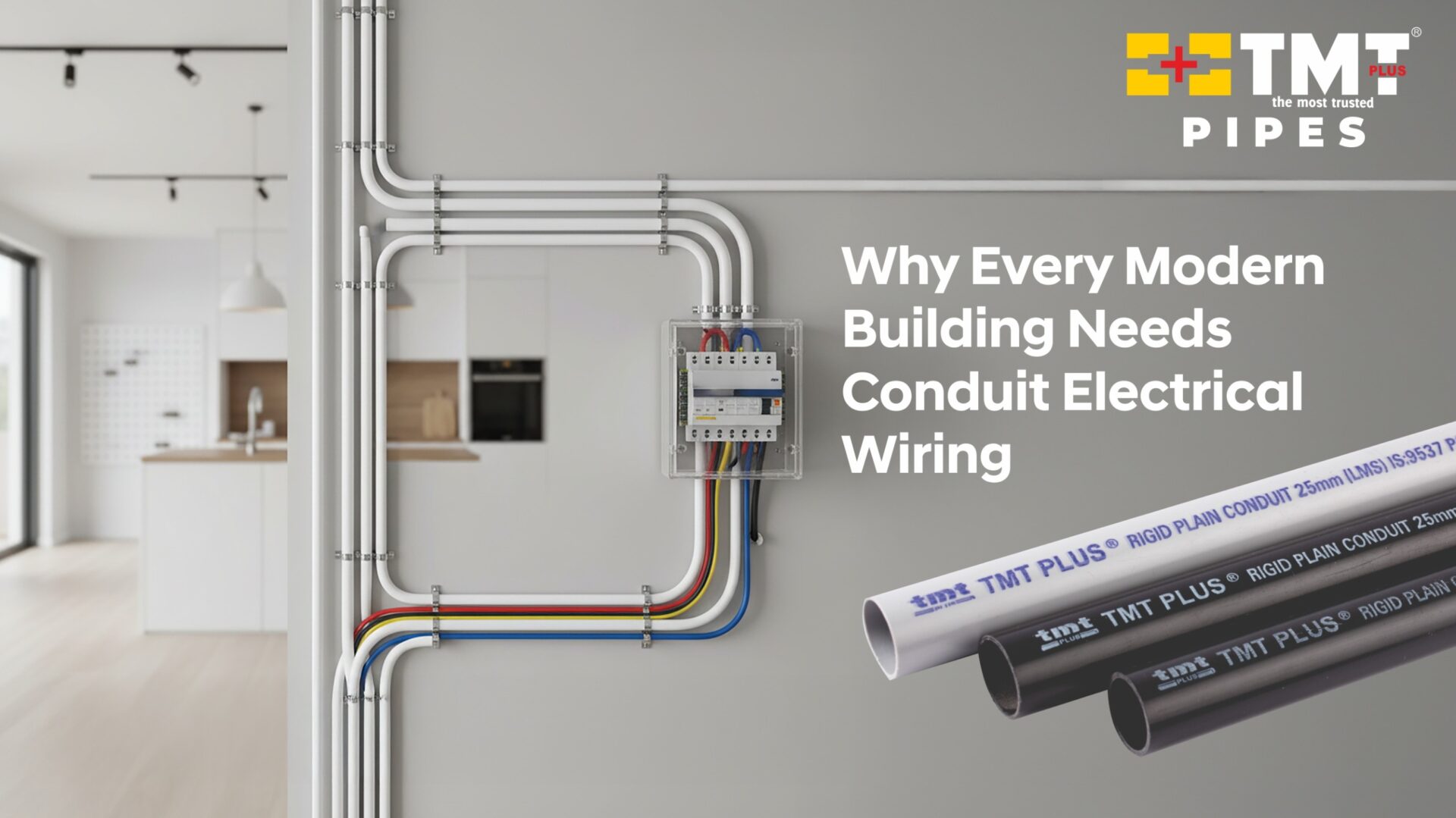

The role of conduit electrical wiring

In a proper wiring setup, using conduit electrical wiring means the cables are placed inside a dedicated protective tube or channel. This approach offers multiple benefits:

- The cables are shielded from mechanical stress and external damage.

- It becomes easier to replace or upgrade wiring in future without tearing into finishes.

- The installation remains cleaner and more organised, improving aesthetic and inspection access.

At TMT Plus, their uPVC conduit pipes are specifically designed for cable routing, protecting wires from shocks, mechanical stress, and abrasion.

Here are some of the major components that a well-designed wiring system will include, and how they fit together with the conduit approach:

- PVC conduit pipe – A sturdy, non-conductive tube in which cables run.

- Electrical conduit pipe – A more general term for any tube designed for protecting electrical cables (PVC, uPVC or metal).

- Casing patti – A component used to hold or cover wiring in surface installations where cables run externally along walls.

- Metal box – A fitting for junctions or terminations in metallic installations, offering a grounding path and robust housing.

- Electrical box – More generic than metal box; a place where wires terminate, switchboards, sockets or junctions.

- Concealed box – Installed flush in the wall or floor, so the wiring and connections are hidden behind the finish.

- PVC pipe sizes – It’s essential to choose the correct diameter for conduit runs so cables sit comfortably, with room for future expansion.

- Plumbing fittings CPVC – Although not directly electrical, many buildings have mixed installations of plumbing and electrical systems. Using quality CPVC fittings ensures that water systems don’t interfere with wiring runs.

- SWR pipe – For sewage and wastewater systems. Important to consider routing of water-bearing pipes in the same structure, so they don’t cross or interfere with electrical runs.

- Water storage tank, water plastic tank, water tank – While these items are used for fluid storage, their positioning relative to electrical systems matters: electrical conduits must be routed so that any leakage or maintenance of tanks does not compromise wiring.

How conduit installation helps organise and protect your cables

- 1. Grouping and routing: By running cables inside a conduit or pipe, you can group all related circuits in a structured route. This makes future modifications simpler—each pipe houses a consistent bundle, reducing confusion.

- 2. Physical protection: The pipe shields cables from nails/screws during renovation, from abrasions during installation and from impacts during everyday use. A robust pipe helps maintain insulation integrity.

- 3. Moisture and chemical deterrence: Especially in structures where plumbing fittings (CPVC) or sewage runs (SWR) exist, separation matters. Using dedicated conduits for wiring ensures that moisture or corrosive elements do not damage cable insulation.

- 4. Ease of inspection and replacement: With clear conduit runs, when you open a concealed box or an electrical box, you can trace cables more easily. If a conduit proves faulty, you simply pull a new inner cable rather than rerouting from scratch.

- 5. Neat finish and future-proofing: Using flush fittings like concealed boxes improves aesthetics, and allows for expansion: you may use slightly larger PVC pipe sizes now so you have room later for extra circuits. Good systems at the start always cost less to expand later.

- 6. Compliance and safety: Many building codes and standards encourage or require conduit use, especially in commercial settings. A system that includes metal boxes and proper conduit routing provides an additional layer of compliance and grounding.

Why choose TMT Plus for your conduit and wiring accessories

- We are a pioneer in polymer product manufacturing, including pipes and plastic tanks.

- TMT Plus conduit pipes are explicitly designed for electrical installations, protecting cables from shocks and abrasion.

- Our product range also covers metal boxes & accessories, making it easier to source all necessary parts from one trusted manufacturer.

- With a strong presence across India, they are well positioned for supply, support and after-sales services.

Practical tips for installing conduit electrical wiring in your next project

- Select the correct size: Choose a diameter of PVC pipe that gives enough clearance for wires plus future additions.

- Avoid overlapping with plumbing runs: Keep your electrical conduit separate from major plumbing, such as your water tank or sewage lines (SWR pipe), to reduce the risk of damage or moisture.

- Plan junctions carefully: Use concealed box or surface electrical box, or metal box options at every change of direction, termination point or at outlets.

- Use quality fittings: Make sure to match your conduit with high-grade bends, junctions and end-caps engineered for durability. TMT Plus’s range ensures these qualities.

- Label and document routes: Once the wiring pipe network is fixed, record its path for future maintenance.

- Integration with other building services: Ensure your electrical conduit layout complements your water storage tank location, plumbing fittings (CPVC), mechanical ventilation ducts, etc.

Using conduit electrical wiring provides a systematic, protective, future-ready framework for your cables. By choosing a credible manufacturer such as TMT Plus and integrating the right product set—PVC conduit pipe or electrical conduit pipe, casing patti, metal box or concealed box, correct PVC pipe sizes—you can significantly reduce risks like insulation damage, electrical faults or messy cable runs. Moreover, while your neighbours are still improvising wiring routes around their water plastic tank and plumbing lines, you’ll have a clean, safe installation that blends form and function.

If you’re planning an installation—or considering an upgrade—look at TMT Plus’s offerings of wiring pipe solutions, switches, boxes and full-range accessories. A well-organised wiring network isn’t just good engineering—it’s peace of mind.